Take a moment to look around you. You will notice that from your house to the roads that you travel on, there is cement everywhere. It forms the base of our present-day world. However, the startling fact is that producing normal cement releases close to 8% of the global carbon dioxide.

The total amount of carbon released from making regular cement is more than all the carbon from every plane in the world. That’s a huge problem. As cities grow fast and buildings go up everywhere, we’re using many materials that harm the planet. Cement is one of the worst.

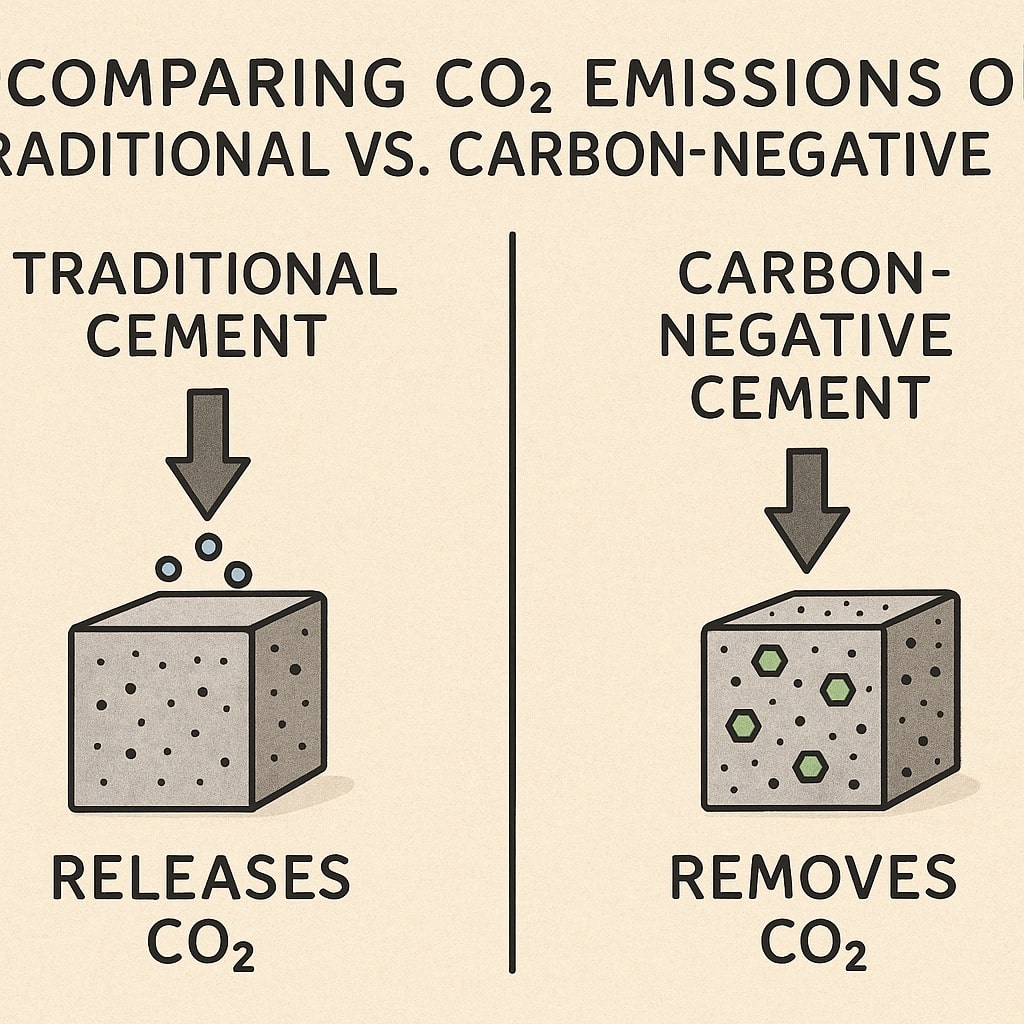

Here comes carbon-negative cement, a revolutionary invention that completely reverses the traditional approach. Instead of releasing carbon dioxide into the environment, this new type of cement can remove carbon from the air. Does it sound impossible? Let’s see if this creation can help us construct our cities while simultaneously preserving nature.

Why Regular Cement Is a Climate Nightmare

To understand the importance of new solutions, it is essential to first examine the issues with conventional cement.

Portland cement is the type we have used for over one hundred years. Its production starts with the mining of limestone. It is then heated in a kiln to temperatures ranging from 1450°C (2640°F) to extreme temperatures. The removal of carbon contained within the limestone is termed “calcination” and requires the limestone to release the carbon it has stored for millions of years.

The circumstances surrounding the manufacture of each ton result in the release of almost a ton of CO2 into the atmosphere. The total cement production exceeds 4 billion tons annually, so there is plenty of trouble ahead.

According to the International Energy Agency, “Cement is both the backbone of modern development and one of the greatest environmental challenges.” And construction isn’t slowing down any time soon. It is estimated that construction will increase by an additional 25% by 2030, indicating that demand will continue to rise.

READ MORE: How Climate Change Is Creating a New Class of Refugees?

The Cement Paradox

This is the tough part. The world’s poorest countries desperately need more infrastructure, such as buildings, roads, and dams, to lift people out of poverty. They need cement. Meanwhile, our planet needs us to slash carbon emissions quickly. This is what experts refer to as “the cement paradox.” We need it to build better lives but making it the traditional way hurts our future.

The cement paradox reveals several key tensions:

- Development needs vs. climate goals: Emerging economies need infrastructure but can’t follow the high-carbon path of developed nations

- Short-term costs vs. long-term benefits: Greener cement often costs more upfront but saves money over time through durability and avoids climate damage

- Proven technology vs. innovation risk: Builders trust traditional cement’s track record but must embrace newer alternatives to meet climate targets.

“We can’t simply stop using cement,” explains Dr. Sarah Chen, a materials scientist at Stanford University. “We need to reinvent it instead.”

Understanding Carbon-Negative Cement Technologies

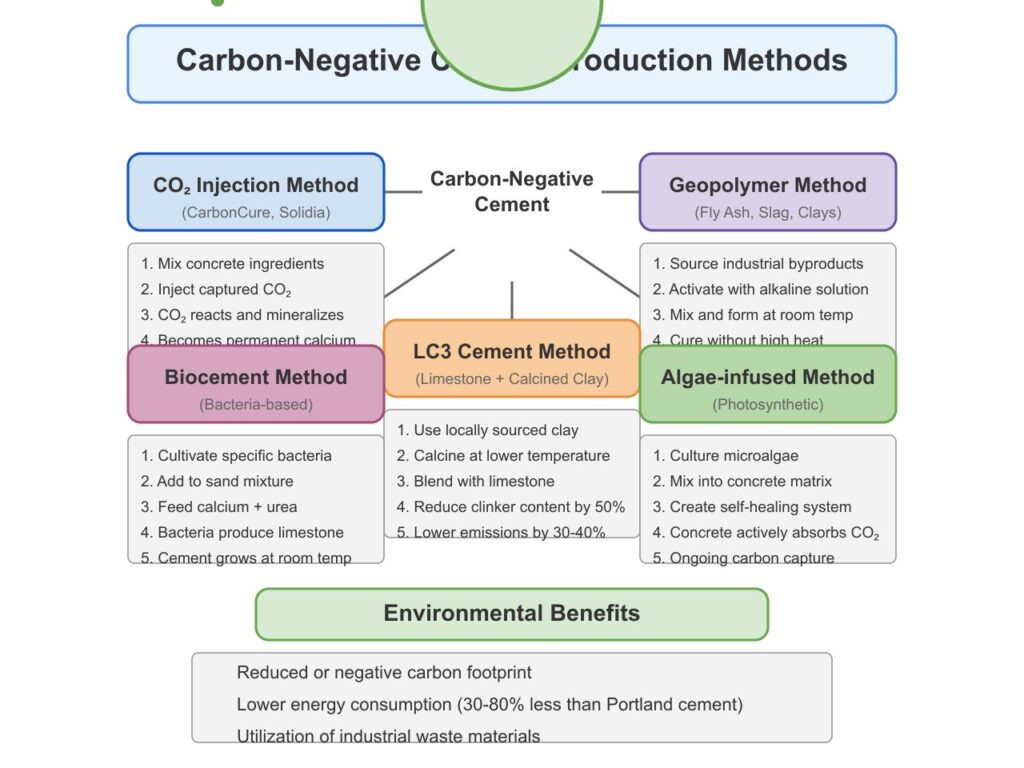

CO2- Restoring Technologies

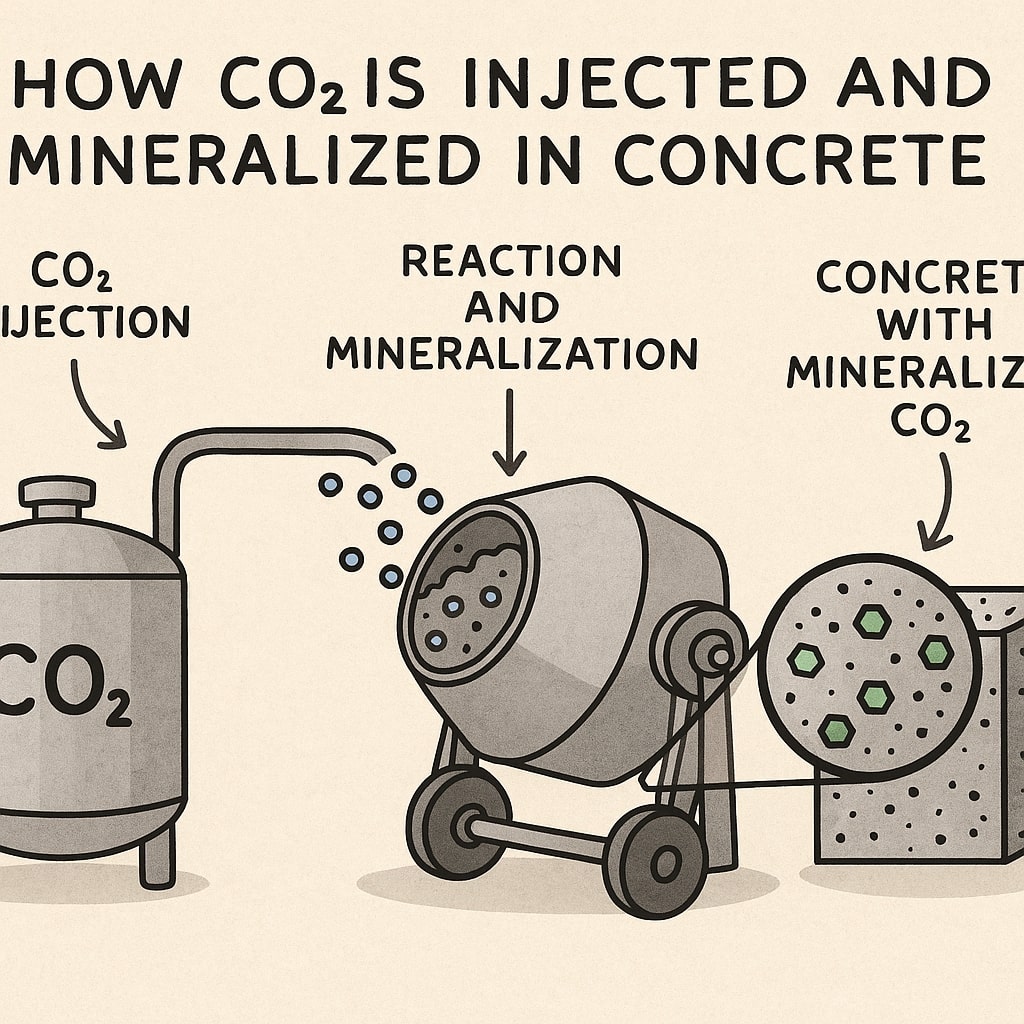

Restore concrete processes are particularly attractive for the development of carbon-negative cement. CarbonCure and Solidia are among the first companies to capture carbon for concrete during the curing phase and inject it into the concrete, which can later be utilized.

How it works

CO2 gas is pumped into raw concrete, where it is transformed into solid minerals that strengthen the concrete.

The carbon becomes part of the building material and stays locked up, potentially for centuries.

The CO2-curing process works in four simple steps:

- Capture: CO2 is collected from industrial emissions or directly from the air

- Purification: The CO2 is cleaned and compressed into a usable form

- Injection: The gas is precisely added during the concrete mixing process

- Mineralization: Chemical reactions transform CO2 into solid calcium carbonate

“This process not only reduces the cement needed by up to 30%, but it also permanently mineralizes that carbon dioxide,” explains Tom Schuler, CEO of Solidia Technologies. “The concrete is helping clean up the air.”

A single CarbonCure facility can lock away as much CO2 as 500 acres of forest while making concrete stronger. That is concrete that fights climate change.

Alternative Binding Materials

Another approach discards the traditional cement formula altogether and utilizes entirely different materials.

For example, geopolymers can be produced from coal waste products, such as fly ash, or steel mill byproducts, such as slag. These products would otherwise be sent to a landfill but can be transformed into alkaline solutions to produce cement-like binders far below the temperature required to sequester large quantities of carbon.

Wagners, an Australian company, has developed Earth Friendly Concrete using geopolymer technology, which reduces emissions by as much as 70% compared to traditional concrete.

There is LC3 (Limestone Calcined Clay Cement), which replaces as much as 50% of clinker (which is the most carbon-intensive part of cement) with activated clays and limestone. This is particularly useful for some developing countries because the materials are abundant and do not require sophisticated processing technology.

Dr. Karen Wilson, a civil engineer specializing in sustainable infrastructure, says, “What makes these alternatives so exciting is that they often use waste materials and require much less energy to produce.”

Biological Approaches

Copying nature is also an interesting area of development, capturing the focus. For billions of years, living organisms have been manufacturing their building cement, like in the case of coral reefs and seashells.

BioMASON is one of the companies that has been growing cement using bacteria. Through some biotechnological alteration processes, instead of heating limestone, they feed the bacteria calcium and urea. This process enables the initiation of a metabolic response in the bacteria, leading to the production of biocement at a peaceful ambient temperature, with low carbon emissions.

Algae-infused concrete is another area of research where concrete can actively absorb CO2 throughout its lifetime. This ability is like a building material that becomes greener with age. How about cities that clean the air only by existing?

Ginger Krieg Dosier, founder of bioMASON, puts it perfectly: “We’re not reinventing concrete; we were returning to how nature has been building strong, durable structures all along.”

Real-World Applications and Case Studies

Buildings That Fight Climate Change

The negative environmental impact of cement is no longer a lab experiment. It has been used in real-life constructions all over the world.

The construction of a new building in Atlanta, Georgia, known as Ponce City, required the addition of approximately 725,000 square feet of office space. In building 725 Ponce, CarbonCure technology was utilized during construction, helping to prevent approximately 680,000 conservational tons of CO2 from entering the environment. That’s comparable to about 800 acres of flourishing for a year.

In Toronto, Canada, the Hullmark Center also features a carbon-embedded concrete foundation, which not only uses carbon but also reduces emissions; the concrete used in this foundation is around 10 percent stronger after undergoing this process.

The building’s developers found it cost-effective to be the same as traditional concrete.

Even more ambitious is the plan for Masterplanet in Copenhagen, Denmark, a neighborhood development that aims to utilize biological concrete containing algae, which will actively absorb carbon throughout its lifespan, creating buildings that become more climate-friendly with age.

“What sells our clients isn’t just the environmental benefits,” explains architect Maya Gonzalez, who has designed three buildings using carbon-negative materials. “It’s that the concrete is often stronger, more crack-resistant, and doesn’t cost significantly more.”

Performance in the Real World

How do these green alternatives stack up against traditional cement?

Tests show that many carbon-negative cements develop strength faster than traditional concrete, allowing construction to proceed more quickly. They often exhibit better resistance to chemicals and saltwater, which could result in longer-lasting infrastructure and fewer repairs.

In durability tests, some biocement formulations have outperformed traditional concrete in freeze-thaw cycles, making them potentially better for cold climates. Concrete cured with CO2 has shown up to 30% better crack resistance in certain applications.

“We were skeptical at first,” admits Frank Torres, a construction manager who’s worked with several alternative types of cement. “But these materials have passed every test we’ve thrown at them. In some ways, they’re better products.”

Cost and Market Challenges

The biggest hurdle isn’t technical performance. It’s cost and industry habits. Construction is notoriously slow to adopt new technologies, and many builders are hesitant to try materials without decades of proven use.

| Technology Type | Carbon Reduction | Cost Premium | Market Readiness |

| CO2-Curing | 5-30% | 5-15% | Commercial |

| Geopolymers | 40-80% | 10-25% | Early Commercial |

| LC3 Cement | 30-40% | 5-15% | Commercial |

| Biocement | 70-100% | 25-40% | Pilot Stage |

| Algae-infused | 100%+ | 30-50% | Research Stage |

Currently, most carbon-negative cements cost 15-30% more than traditional cement, though prices are dropping quickly as production scales up. However, when factoring in carbon taxes (already implemented in many countries) and the longer lifespan of these materials, the lifetime cost can be lower.

“The industry doesn’t change materials easily, and for good reason: buildings need to stand for decades,” explains Dr. Wilson. “But climate change isn’t waiting for us to get comfortable with new materials.”

Environmental and Economic Implications

When scientists look at the entire lifecycle of carbon-negative cement, from raw material extraction to manufacturing to use in buildings and eventual demolition, the environmental benefits go beyond just carbon.

Many of these new cements require less water, produce fewer air pollutants, such as sulfur dioxide, and generate less waste. Some even improve indoor air quality by absorbing toxins throughout their lifetime.

A comprehensive study by the University of California found that the widespread adoption of carbon-negative cement technologies could reduce global CO2 emissions by up to 5% by 2030, a significant portion of what is needed to meet our climate goals.

“We’re not just talking about a slightly better version of an old material,” says environmental scientist Dr. James Kim. “We’re talking about transforming one of the world’s biggest carbon sources into a carbon sink.”

Economic Barriers and Opportunities

The cement industry employs millions worldwide and represents trillions in infrastructure. Changing it won’t happen overnight.

The biggest economic barrier is the massive investment that has already sunk into traditional cement plants. Converting these facilities to produce carbon-negative alternatives can cost hundreds of millions of dollars, a sum many companies are reluctant to spend unless compelled to do so.

However, the opportunities are equally massive. The market for green building materials is projected to reach $523 billion by 2027, growing at a rate of over 8% annually. Early adopters of carbon-negative technologies are positioning themselves to capture this growth.

“Companies clinging to traditional cement are like film companies that ignore digital cameras,” warns economist Patricia Ramirez. “This isn’t just an environmental issue, and it’s about which businesses will survive the next 20 years.”

Policy Support for a Concrete Revolution

Governments worldwide are beginning to encourage the concrete industry to adopt greener alternatives through both incentives and regulations.

Countries such as Sweden, France, and Canada have implemented carbon taxes that make traditional cement production more expensive. Others, such as Singapore, offer tax breaks and expedited permits for buildings that use low-carbon materials.

Perhaps most importantly, government procurement policies are undergoing a shift. When the government itself, often the biggest builder in any country, demands green concrete for its roads, dams, and buildings, it creates the market stability needed for large-scale investment in new technologies.

“The policies that will drive the fastest change aren’t bans on old cement,” explains policy researcher Aisha Johnson. “They are guaranteed markets for new cement. When manufacturers know they’ll have customers, innovation accelerates dramatically.”

Frequently Asked Questions

What exactly is carbon-negative cement, and how does it differ from regular cement?

Carbon-negative cement is a new kind of building material that actually absorbs more CO₂ than it emits. It releases tons of carbon during production, as traditional cement. These newer versions trap CO₂ inside the concrete or use alternative binders that require far less energy to make.

Is carbon-negative cement strong and safe enough to replace regular cement?

Yes, many forms of carbon-negative cement are not only just as strong but can also be more durable and crack-resistant. Builders using CO₂-cured or bio-based cement have reported faster times and better long-term performance, even in tough weather.

Why isn’t carbon-negative cement used everywhere yet?

The biggest barriers are cost, unfamiliarity, and habit. Traditional cement is cheaper (for now), and the construction industry is slow to adopt new materials. But as green materials become more affordable and climate regulations tighten, adoption is growing fast.

Are there any real buildings using carbon-negative cement already?

Absolutely. Buildings in Atlanta, Toronto, and Copenhagen have already used these new materials. In some cases, the concrete even costs the same as traditional options. It has benefits like lower emissions and improved strength.

What can governments and everyday people do to support this transition?

Governments can update building codes, fund green construction, and prioritize eco-friendly materials in public projects. Individuals can advocate for sustainable developments, support green building certifications. It raises awareness about the environmental cost of traditional concrete.

Conclusion

So, can we build our cities without destroying the planet? The answer is increasingly “yes.” Carbon-negative cement isn’t just possible. It’s already here, already being used, and already proving itself in real buildings around the world.

Technology exists and works well. The remaining challenges aren’t technical but economic and cultural, stemming from the natural resistance to change in an industry where failure can mean collapsed buildings and lost lives.

Therefore, change is forthcoming, driven by climate necessity, market opportunities, and policy pressures. Many experts believe that by 2040, traditional Portland cement could become an exception rather than the rule, used only in specialized applications where alternatives can’t compete.

References

- International Energy Agency. (2023). “Cement Technology Roadmap: Carbon Emissions Reductions up to 2050.” IEA Publications.

- Zhang, J., et al. (2023). “Life Cycle Assessment of Novel Carbon-Negative Cement Alternatives.” Journal of Cleaner Production, 389, 135651.

- World Green Building Council. (2024). “Bringing Embodied Carbon Upfront.” WGBC Report.

- United Nations Environment Programme. (2023). “2023 Global Status Report for Buildings and Construction.” UNEP Publications.

- Lehne, J., & Preston, F. (2023). “Making Concrete Change: Innovation in Low-Carbon Cement and Concrete.” Chatham House Report.

- Cao, Z., et al. (2023). “The Sponge Effect: The Potential of Bio-Based Materials in Carbon-Negative Construction.” Nature Sustainability, 6(5), 456-464.

John is a professional blogger and passionate advocate for environmental sustainability. With years of experience exploring eco-friendly practices and green innovations, he shares insightful articles on Planet Flagship to inspire a sustainable future. John’s expertise lies in making complex environmental topics accessible and actionable, empowering readers to make meaningful changes for the planet.