Lithium-ion batteries, which are crucial to the operation of electric vehicles (EVs), are often regarded as a cleaner alternative to traditional internal combustion engine vehicles. However, like any technology, they have their own environmental costs, particularly in terms of resource extraction, production, and disposal. Here’s a closer look at some of the darker aspects of lithium batteries and the Environmental Cost of Electric Vehicles.

Mining for Lithium and Other Raw Materials

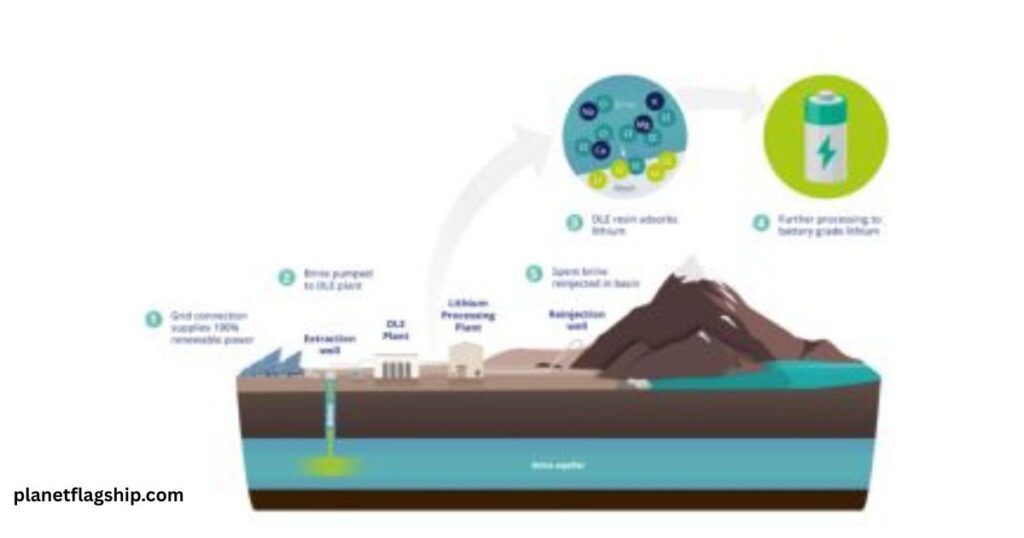

Lithium Extraction: Lithium is the key component in most modern electric vehicle batteries. However, the extraction process, particularly from sources such as lithium brine pools or hard rock mining, can have significant environmental impacts.

Water Use: Lithium brine extraction requires enormous amounts of water, which can deplete local water supplies, particularly in arid regions such as the Atacama Desert in Chile or the Lithium Triangle in South America. This water scarcity impacts local farming and communities.

Habitat Destruction: Mining can lead to habitat destruction and biodiversity loss, particularly in sensitive ecosystems. The mining process can also result in land degradation.

Toxic Chemicals: Mining for lithium often involves the use of harmful chemicals, such as sulfuric acid, which can contaminate nearby water sources if not properly managed.

Cobalt and Nickel Mining: Many lithium-ion batteries also contain cobalt and nickel, which are often mined under similarly destructive conditions.

Cobalt: A large portion of the world’s cobalt comes from the Democratic Republic of Congo, where mining practices have been associated with child labor, human rights abuses, and unsafe working conditions. Additionally, cobalt mining can lead to environmental degradation and pollution.

Nickel: Nickel mining can also result in deforestation, habitat destruction, and the release of harmful emissions into the air and water.

READ MORE: How Youth Activists Are Leading the Fight for Climate Change?

Energy Consumption in Manufacturing

The production of electric vehicles and their batteries is an energy-intensive process. While the environmental impact of EVs in use is lower than that of conventional vehicles, the manufacturing process can be carbon-intensive, particularly if the electricity used is generated from fossil fuels.

Battery Production Emissions: Studies have shown that producing a lithium-ion battery can generate significant carbon emissions. The energy required to mine and process materials, manufacture the batteries, and assemble the EVs themselves can contribute to a higher initial carbon footprint compared to conventional vehicles.

Battery Disposal and Recycling

End-of-Life Concerns: As electric vehicles reach the end of their lifespan, disposing of their batteries becomes an increasingly challenging task. Batteries require proper management because they contain valuable and hazardous materials.

Toxic Waste: If lithium-ion batteries are not disposed of properly, they can leach toxic substances, such as heavy metals, into the environment, polluting soil and water. o

Recycling Challenges: While some progress has been made in recycling lithium-ion batteries, the infrastructure for recycling at scale is still limited. The process itself is complex and energy-intensive. Only a small percentage of battery materials are currently recycled effectively, resulting in a significant amount of material going to waste.

Carbon Footprint Over Time

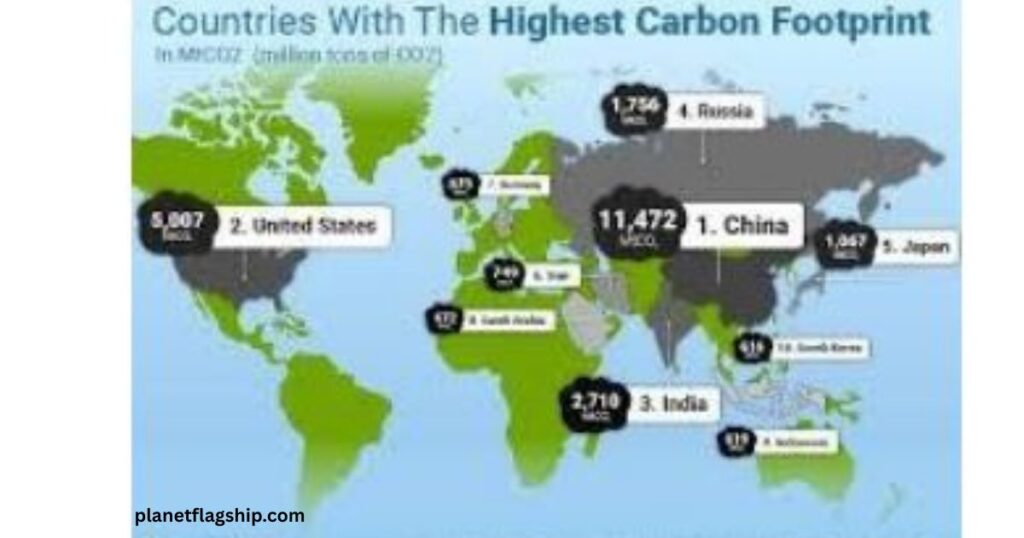

While electric vehicles tend to have a lower lifetime carbon footprint compared to conventional vehicles (especially when powered by cleaner energy sources), the overall carbon savings depend heavily on where the car is charged.

The environmental benefits of EVs diminish in regions where fossil fuels (coal, natural gas) primarily generate electricity. It may take years for an EV to offset the emissions produced during its manufacturing, particularly the battery, depending on the carbon intensity of the local grid.

The Rush for Raw Materials

With the rapid growth of the electric vehicle market, demand for raw materials used in batteries is skyrocketing. This can lead to increased mining activity, often in regions where environmental regulations are weak or enforcement is lax.

Resource Depletion: Concerns exist that as demand for lithium, cobalt, and other critical battery materials increases, these resources may become scarce, driving up prices and leading to unsustainable extraction practices.

Geopolitical Issues: The concentration of critical materials in a few countries (e.g., lithium in Chile and Argentina, cobalt in the Democratic Republic of the Congo, or the DRC) can lead to geopolitical tensions and supply chain vulnerabilities.

Social Impacts

As mentioned, mining for materials like cobalt often involves the exploitation of labor, including child labor, and unsafe working conditions. These ethical concerns raise questions about the social costs of the transition to electric vehicles, especially when the raw materials are sourced from regions with limited labor protections and governance.

Community Displacement: In some cases, large-scale mining operations can lead to the displacement of local communities, disrupting traditional ways of life and exacerbating poverty.

Possible Solutions

Advances in Recycling: Investing in better recycling technologies and increasing the rate of battery recycling can help mitigate some of the environmental costs associated with battery disposal.

Sustainable Mining Practices: There is a growing push for more sustainable and ethical sourcing of lithium, cobalt, and other critical materials, accompanied by stricter environmental regulations and fair labor standards.

Battery Innovation: Research into alternative battery technologies that use less harmful or more abundant materials could help reduce the environmental impact of EV batteries in the future. For example, solid-state batteries or sodium-ion batteries could be less environmentally damaging.

Renewable Energy Integration: As the grid continues to decarbonize with an increasing number of renewable energy sources (such as solar, wind, and hydro), the overall environmental footprint of electric vehicles will decrease. Encouraging the use of renewable energy for EV charging can make a significant difference.

FAQs: The Dark Side of Lithium Batteries and EVs

Why are lithium-ion batteries considered harmful to the environment?

Lithium-ion batteries require intensive mining, water use, and chemicals that harm ecosystems. Poor disposal and limited recycling infrastructure also release toxic waste into soil and water.

How does lithium mining affect local communities?

Lithium extraction depletes scarce water supplies in arid regions like Chile’s Atacama Desert, threatening agriculture and local livelihoods. In some areas, large-scale mining displaces entire communities.

What are the ethical issues with cobalt mining?

A large share of cobalt comes from the Democratic Republic of Congo, where child labor, unsafe working conditions, and human rights abuses are widespread. These practices raise serious ethical concerns.

Do electric vehicles have a higher carbon footprint than gas cars?

Initially, yes. EV battery production is highly energy-intensive. However, over time, EVs generally offset these emissions—especially when charged with renewable energy sources.

What happens to EV batteries after their life cycle?

Without proper recycling, old batteries leak heavy metals into soil and water. Current recycling systems recover only a small percentage of materials, making large-scale waste management a growing problem.

Conclusion

While electric vehicles are a step forward in reducing greenhouse gas emissions and air pollution, the full environmental cost is not without its challenges. The extraction of raw materials, energy-intensive manufacturing, and issues related to battery disposal and recycling all contribute to the hidden environmental toll of EVs. Addressing these issues requires a holistic approach that focuses on sustainable mining practices, better recycling technologies, and continued innovation in battery design.

References

International Energy Agency (IEA)—Global EV Outlook

“Battery Recycling: The Green Future of the Electric Vehicle” by J. J. Lennon –

“Environmental and social impacts of the global lithium supply chain”

“Impact of electric vehicle battery production on the environment and human health: A review”

Government and Organizational Reports

United Nations Environment Programme (UNEP)—”Minerals and Metals for the Clean Energy Transition”

“The Environmental Impact of Lithium Batteries”—Scientific American

“Electric Vehicle Batteries: Materials and Recycling”—U.S. Department of Energy (DOE)

News Articles and Popular Media

“Lithium: A Battery of Questions”—The New York Times is available here.

“The Hidden Cost of Green Energy: EV Battery Mining”—The Guardian. Available here.

“Electric Cars: The Environmentally Friendly Alternative?” – BBC News is available here.

Websites & Industry Resources

World Economic Forum—”The Hidden Environmental Cost of Electric Vehicles”

The International Cobalt Institute (ICI) is available here.

Greenpeace—”TheImpact of Electric Cars on the Environment” o Available here

John is a professional blogger and passionate advocate for environmental sustainability. With years of experience exploring eco-friendly practices and green innovations, he shares insightful articles on Planet Flagship to inspire a sustainable future. John’s expertise lies in making complex environmental topics accessible and actionable, empowering readers to make meaningful changes for the planet.