Introduction

Carbon capture refers to the process of capturing carbon dioxide emissions produced from sources, such as fossil fuel power plants in electricity generation and industrial processes (IPCC, 2005). The captured CO₂ may be further transported for storage or utilization depending upon the need. Utilization involves using the captured CO₂ in various applications, such as converting it into fuels, chemicals, or other products, referred to as Carbon Capture and Utilization (CCU).

The storage aspect of CCUS involves the long-term storage of captured CO₂ in locations where the gas can be isolated from the atmosphere, such as deep ocean sites, depleted oil and gas fields, or deep saline aquifers. This process is known as Carbon Capture and Storage (CCS) and is crucial for mitigating climate change by preventing CO₂ from entering the atmosphere.

History and current state of Carbon Capture and Storage

Carbon Capture and Storage (CCS) is a climate mitigation technology that captures carbon dioxide (CO₂) emissions from industrial sources, preventing them from entering the atmosphere and contributing to global warming (IPCC, 2005). The concept of CCS dates back several decades, with early research exploring methods to reduce greenhouse gas emissions from the combustion of fossil fuels.

Early Developments (1970s – 1990s)

The development of CCS began in the early 1970s to reduce CO₂ emissions. One of the earliest applications of CO₂ capture was in the oil and gas industry, where carbon dioxide was injected into depleted oil fields to enhance oil recovery (EOR) (Benson et al., 2012). This process, known as Enhanced Oil Recovery (EOR), demonstrated that CO₂ could be stored underground while also improving oil production.

During the 1990s, CCS gained attention as a potential large-scale strategy for mitigating climate change. Governments and research institutions conducted feasibility studies and pilot projects to explore the technical and economic viability of CCS (Rubin et al., 2005). The International Panel on Climate Change (IPCC) acknowledged CCS as an option for reducing emissions from fossil fuel combustion (IPCC, 2005).

READ MORE: Are We Ready for the Next Climate-Induced Pandemic?

Growth and Early Implementations (2000s – 2010s)

Large-scale carbon capture and storage (CCS) projects began emerging in the early 2000s. One of the pioneering commercial CCS facilities was Norway’s Sleipner Project, which started storing CO₂ in 1996 (Torp & Gale, 2004). This project demonstrated the feasibility of underground CO₂ storage and encouraged further investment in CCS technology.

Recent Advancements (2020s – Present)

In recent years, CCS has evolved in tandem with advancements in climate policies and carbon capture and storage (CCS) technologies. The Paris Agreement (2015) suggested that there is an urgency to reduce emissions, prompting nations to explore CCS as part of their climate strategies (UNFCCC, 2015). Emerging CCS innovations include Carbon Capture, Utilization, and Storage (CCUS), which integrates CO₂ reuse in industrial applications, such as the production of synthetic fuels and construction materials (Mac Dowell et al., 2017).

• Current state

Carbon capture and storage (CCS) has seen significant advancements in recent years, with global.

CO₂ capture capacity exceeds 50 million tons annually and is expected to triple by 2030. As of 2023, approximately 30 large-scale CCS facilities are operating globally, capturing millions of tons of CO₂ annually, which highlights the growing but still limited deployment of this technology. Governments and industries are increasingly investing in CCS technologies to meet emissions targets and drive decarbonization efforts.

Several countries are making strides in CCS deployment. In Texas, USA, the Environmental Protection Agency (EPA) has issued draft permits for underground carbon storage, marking a step forward in direct air capture (DAC) projects. Meanwhile, Western Australia is expanding its carbon capture, utilization, and storage (CCUS) initiatives, with projects capable of storing over 20 million tons of CO2 per year.

Former UK Prime Minister Tony Blair has argued that CCS should be central to climate strategies, emphasizing that current net-zero policies are unrealistic without technological solutions like CCS. While CCS is gaining momentum, experts stress the need for policy support, financial incentives, and innovation to make it commercially viable on a large scale.

Pakistan is gradually exploring carbon capture and storage (CCS) as part of its climate strategy. The country has committed to reducing greenhouse gas emissions by 60% by 2030, with 35% of this target dependent on international financial support. However, CCS deployment faces challenges due to policy gaps, infrastructure limitations, and high costs.

Studies indicate that CCS could help reduce emissions by 18 million tons under Pakistan’s Nationally Determined Contributions (NDCs) scenario, potentially achieving net-zero status by 2050. There are several industries in Pakistan exploring CCS technologies:

The cement industry is exploring technologies such as post-combustion carbon capture to reduce emissions from cement production.

Power Generation: CCS is being considered for coal-based power plants to mitigate CO2 emissions.

Steel and Fertilizer Industries: These sectors are investigating CCS applications to capture emissions from iron & steel production and ammonia-based fertilizers.

Types of Carbon capture technologies

Carbon capture technologies play a crucial role in mitigating climate change by reducing greenhouse gas emissions from industrial processes and energy production. These technologies are designed to capture carbon dioxide (CO₂) before it enters the atmosphere, preventing its harmful impact on global temperatures. Over the years, various methods have been developed

to enhance the efficiency of carbon capture, making it a viable solution for achieving sustainability goals and supporting the transition to cleaner energy sources. The following are key technologies used in carbon capture and storage (CCS).

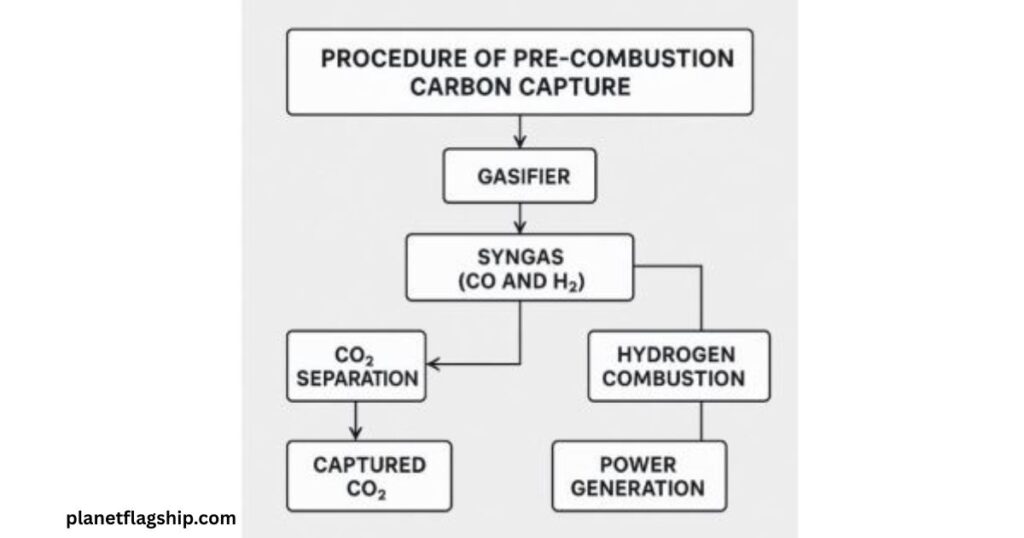

Pre-combustion carbon capture technology

It is the removal of carbon dioxide from fossil fuels before the combustion process. This technology is primarily applied in integrated gasification combined cycle (IGCC) power plants, where fuel is converted into a synthetic gas (syngas) containing hydrogen (H₂), carbon monoxide (CO), and CO₂.

Working of Pre-Combustion Carbon Capture

I. Gasification

Fossil fuels (such as coal or natural gas) are partially oxidized in high-temperature and high-pressure environments to produce syngas. Water-Gas Shift Reaction

The syngas undergoes a chemical reaction where CO reacts with steam (H₂O) to produce more H₂ and CO₂. This step increases the CO₂ concentration, making it easier to capture.

iii. CO₂ Separation

The CO₂ is captured using solvents, sorbents, or membranes, leaving behind a hydrogen-rich fuel that can be used for combustion.

iv. Storage or Utilization

The captured CO₂ is either stored underground or used in industrial applications, such as enhanced oil recovery (EOR) or chemical production.

Advantages of Pre-Combustion Capture

Higher CO₂ Concentration: Easier to capture compared to post-combustion methods.

Lower Energy Penalty: More efficient than capturing CO₂ from flue gases.

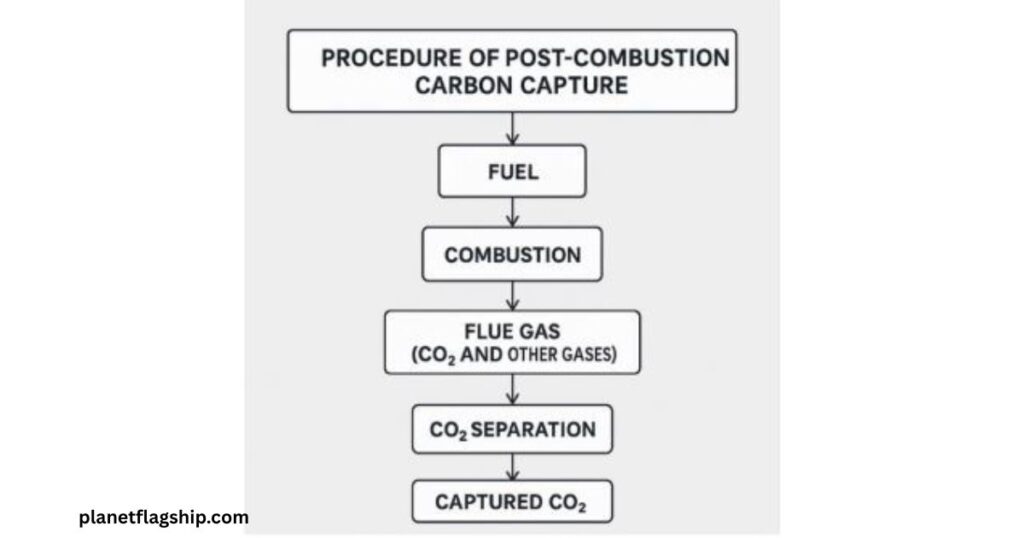

• Post-combustion carbon capture:

Post-combustion carbon capture is a widely used method for removing carbon dioxide (CO₂) from flue gases after fossil fuels are burned. This technology is commonly applied in coal-fired and natural gas power plants, as well as industrial facilities. It enables existing plants to be retrofitted with carbon capture systems without necessitating significant modifications to their combustion processes.

Working of Post-Combustion Carbon Capture

i. Combustion Process

Fossil fuels (coal, oil, or natural gas) are burned in a boiler or furnace, producing flue gases containing CO₂, nitrogen oxides (NOₓ), sulfur dioxide (SO₂), and water vapor.

ii. Flue Gas Cooling and Conditioning

The flue gas is cooled and treated to remove impurities such as particulate matter and sulfur compounds, which can degrade CO₂ capture efficiency.

iii. CO₂ Absorption Using Solvents

The conditioned flue gas is passed through a chemical solvent (amine-based or ammonia-based absorbents) that selectively captures CO₂. The solvent absorbs CO₂, forming a stable compound that can be separated later.

iv. Solvent Regeneration

The CO₂-rich solvent is heated in a regeneration unit, releasing pure CO₂ gas and restoring the solvent for reuse.

v. CO₂ Compression and Storage

The captured CO₂ is compressed to high pressure and transported via pipelines for storage in underground reservoirs or utilization in industrial applications.

Advantages of Post-Combustion Carbon Capture

Easily retrofitted to existing power plants.

Compatible with various fuel types (coal, oil, natural gas). iii. Proven technology with commercial applications.

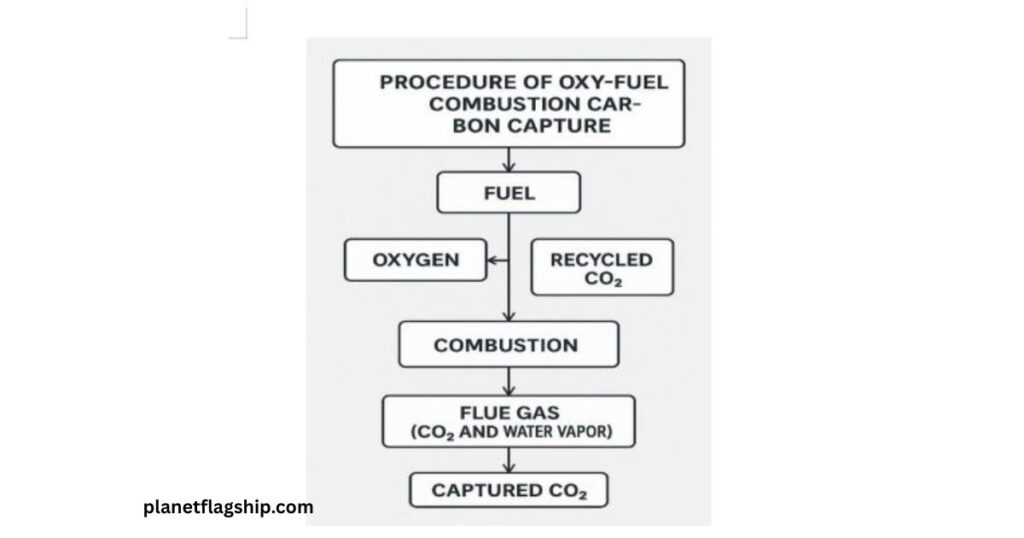

• Oxy-fuel combustion carbon capture:

Oxy-fuel combustion is a carbon capture technology that burns fossil fuels using pure oxygen instead of air. This process produces a high concentration of carbon dioxide, which is much easier to capture and store. It is widely used in different industries to reduce emissions.

Working of Oxy-Fuel Combustion Carbon Capture

i. Oxygen Production

Oxygen is separated from air using cryogenic distillation or membrane-based separation. This ensures that combustion occurs in an oxygen-rich environment, rather than in nitrogen-rich air. ii. Fuel Combustion in Pure Oxygen

Fossil fuels (coal, oil, or natural gas) are burned in pure oxygen, producing a flue gas mainly composed of CO₂ and water vapor. Since nitrogen is not present, the production of nitrogen oxides (NOₓ) is minimized, leading to enhanced efficiency.

iii. Flue Gas Cooling and Water Removal

The flue gas undergoes cooling, causing water vapor to condense and separate, resulting in a highly pure CO₂ stream.

iv. CO₂ Purification and Compression

The CO₂ is then refined to eliminate impurities, such as sulfur compounds, before being compressed for efficient transport and secure storage.

v. CO₂ Storage or Utilization

The captured CO₂ is stored underground in geological formations or used in enhanced oil recovery (EOR) and industrial applications.

Advantages of Oxy-Fuel Combustion

Produces a high-purity CO₂ stream, making capture easier.

Reduces NOₓ emissions, improving air quality.

Can be retrofitted to existing power plants.

• Other technologies:

In addition to pre-combustion, post-combustion, and oxy-fuel combustion, several other carbon capture technologies are gaining attention. Direct Air Capture (DAC) extracts CO₂ directly from the atmosphere using chemical sorbents, offering a potential pathway for negative emissions. Chemical Looping Combustion (CLC) utilizes metal oxides as oxygen carriers, resulting in a concentrated CO₂ stream without the need for additional separation steps.

Membrane-based separation employs selective membranes to filter CO₂ from gas mixtures, thereby enhancing efficiency in industrial applications. Cryogenic separation cools gases to extremely low temperatures, enabling the separation of CO₂, making it suitable for specialized applications. Bioenergy with Carbon Capture and Storage (BECCS) captures CO₂ from biomass combustion, supporting net-negative emissions while producing renewable energy.

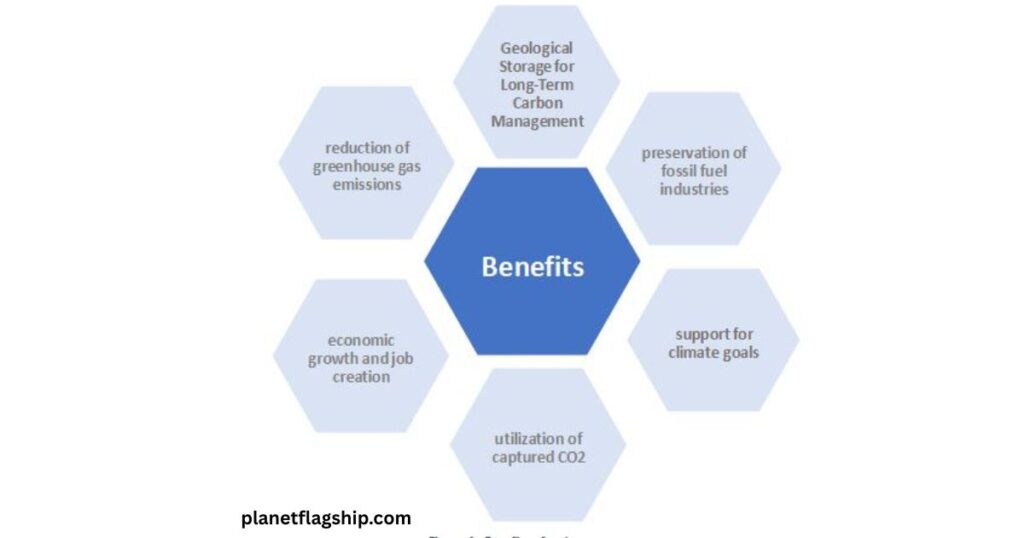

Benefits of carbon capture and storage

Carbon capture and storage (CCS) is a crucial technology in the fight against climate change, offering multiple environmental, economic, and industrial benefits. By capturing carbon dioxide (CO₂) emissions from power plants and industrial facilities, CCS helps reduce greenhouse gas levels and supports the development of sustainable energy solutions.

i Reduction of Greenhouse Gas Emissions

CCS significantly lowers CO₂ emissions from fossil fuel-based industries, preventing large amounts of carbon from entering the atmosphere. Studies suggest that CCS could contribute to 10–55% of total carbon mitigation efforts.

ii Support for Climate Goals

Many countries aim to achieve net-zero emissions by 2050. CCS plays a vital role in meeting these targets by enabling industries to continue operations while reducing their carbon footprint.

iii Enhanced Energy Efficiency

CCS can improve power plant efficiency by utilizing CO₂-based steam cycles, which enhance heat transfer and reduce energy consumption

iv Utilization of Captured CO₂

Captured CO₂ can be repurposed for various applications, including:

-Enhanced Oil Recovery (EOR)– Injecting CO₂ into oil fields to increase extraction efficiency.

-Concrete Strengthening– CO₂ can be used to enhance the durability of concrete structures

-Manufacturing – CO₂ is used in producing chemicals and plastics, such as polyurethanes

v Economic Growth and Job Creation

Expanding CCS operations can create new jobs in engineering, construction, and maintenance, supporting economic growth

vi Preservation of Fossil Fuel Industries

CCS allows industries to continue using fossil fuels while reducing emissions, ensuring energy reliability and affordability

vii Geological Storage for Long-Term Carbon Management

Captured CO₂ can be stored in deep underground reservoirs, preventing its release into the atmosphere and contributing to long-term climate stability.

Challenges and limitations

Carbon capture and storage (CCS) is a promising technology for reducing greenhouse gas emissions, but it faces several technical, economic, environmental, and social challenges that hinder its widespread adoption.

I. High Costs and Energy Consumption

One of the biggest challenges of CCS is its high cost. The process of capturing, transporting, and storing CO₂ requires significant investment, making it economically unfeasible for many industries. Additionally, CCS is energy-intensive, with some estimates suggesting it can consume up to 30% of a power plant’s energy output.

II. Infrastructure and Storage Limitations

CCS requires extensive infrastructure, including pipelines for CO₂ transport and underground storage facilities. Finding suitable geological storage sites is challenging, as not all locations have the necessary conditions for long-term carbon dioxide (CO₂) containment.

III. Risk of CO₂ Leakage

Stored CO₂ must remain underground indefinitely to prevent environmental harm. However, there is a risk of leakage, which could lead to groundwater contamination and health hazards. Natural disasters, such as earthquakes, could also compromise storage integrity.

IV. Public Perception and Regulatory Barriers

Many people are skeptical about CCS due to concerns over safety, effectiveness, and long-term viability. Additionally, regulatory frameworks for CCS are still evolving, making it difficult for companies to navigate legal requirements.

V. Limited Commercial Deployment

Despite its potential, CCS has not been widely adopted due to economic and technical barriers. Only a few large-scale CCS projects are operational, and many planned projects face delays or cancellations due to financial constraints.

Future directions/Future Prospects:

Carbon capture and storage (CCS) is expected to play a critical role in global decarbonization efforts, with advancements in technology, policy support, and market expansion shaping its future. As industries and governments strive to meet net-zero emissions targets, CCS is evolving to become more efficient, cost-effective, and widely adopted.

i. Expansion of CCS Projects

The number of CCS projects worldwide is increasing, with over 700 projects currently in various stages of development. By 2050, the amount of captured CO₂ is projected to reach 6.1 gigatons per year, compared to 45 million tons in 2022.

ii. Integration with Carbon Capture, Utilization, and Storage (CCUS)

Beyond storage, captured CO₂ is being repurposed for industrial applications, including biofuels, synthetic materials, and enhanced oil recovery (EOR). This shift toward carbon utilization is expected to make CCS more economically viable.

iii. Advancements in Capture Technologies

Innovations in direct air capture (DAC), membrane-based separation, and chemical looping combustion are improving CCS efficiency and reducing costs. These technologies are expected to scale up in the coming years, making CCS more accessible.

iv. Policy and Financial Incentives

Governments are introducing carbon pricing mechanisms, tax credits, and subsidies to encourage CCS adoption. The European Union aims to establish a single CO₂ market, while the U.S. Inflation Reduction Act (IRA) provides financial incentives for CCS projects.

v. Cross-Sector Collaboration

Industries such as cement, steel, and power generation are working together to develop shared CCS infrastructure, reducing costs and accelerating deployment

FAQ’s

What is Carbon Capture and Storage (CCS)?

Carbon Capture and Storage (CCS) is a technology that captures carbon dioxide (CO₂) emissions from power plants and industries before they reach the atmosphere. The captured CO₂ is then transported and stored underground in geological formations such as saline aquifers or depleted oil fields.

How effective is CCS in reducing greenhouse gas emissions?

CCS can capture up to 90% of CO₂ emissions from industrial sources. Studies show that CCS could account for 10–55% of global carbon reduction efforts needed to meet net-zero targets by 2050.

What are the main types of carbon capture technologies?

The three main methods are pre-combustion capture, post-combustion capture, and oxy-fuel combustion. Emerging technologies like Direct Air Capture (DAC), chemical looping, and bioenergy with CCS (BECCS) are also gaining importance.

What are the biggest challenges facing CCS adoption?

The main challenges include high implementation costs, energy consumption, infrastructure limitations, risk of CO₂ leakage, and lack of strong regulatory and financial support in many countries.

Can CCS alone solve climate change?

No. While CCS is a powerful tool, it cannot reverse climate change on its own. A holistic strategy combining renewable energy, efficiency improvements, carbon pricing, and behavioral changes is essential to achieve global climate goals.

Conclusion

Carbon capture and storage (CCS) represents both a critical tool and a formidable challenge in the fight against climate change. As the urgency to curb carbon emissions intensifies, CCS technologies ranging from pre- and post-combustion methods to direct air capture offer promising pathways to mitigate environmental damage. Despite its numerous benefits, including reducing industrial emissions and potentially enabling carbon-negative solutions, CCS still faces financial, technical, and regulatory hurdles that must be addressed.

Looking ahead, continued innovation, policy support, and global collaboration will be essential in scaling CCS to make a tangible impact. While carbon capture alone cannot reverse climate change, it remains a powerful component in a broader strategy aimed at building a sustainable and resilient future.

References

Benson, S. M., Cook, P., & Gammer, D. (2012). Carbon capture and storage: Progress and prospects. International Energy Agency.

IPCC. (2005). Carbon Capture and Storage. Intergovernmental Panel on Climate Change.

IEA. (2020). CCS in clean energy transitions. International Energy Agency.

Mac Dowell, N., Fennell, P. S., Shah, N., & Maitland, G. C. (2017). The role of CO₂ capture and utilization in mitigating climate change. Nature Climate Change, 7(4), 243–249.

Rubin, E. S., Davison, J. E., & Herzog, H. J. (2005). The cost of CO₂ capture and storage. International Journal of Greenhouse Gas Control, 1(1), 61–81.

Torp, T. A., & Gale, J. (2004). Demonstrating storage of CO₂ in geological reservoirs: The Sleipner and SACS projects. Energy, 29(9-10), 1361–1369.

UNFCCC. (2015). Paris Agreement. United Nations Framework Convention on Climate Change.

Wilson, M., & Monea, M. (2004). IEA Weyburn CO₂ monitoring and storage project. Petroleum Society of Canada.

Osman, A. I., Hefny, M., Abdel Maksoud, M. I. A., Elgarahy, A. M., & Rooney, D. W. (2020).

Recent advances in carbon capture storage and utilisation technologies: A review. Environmental Chemistry Letters, 19(2021), 797–849. Springer.

Thiedemann, T. M., & Wark, M. (2025). A compact review of current technologies for carbon capture as well as storing and utilizing the captured CO₂. Processes, 13(1), 283. MDPI.

Gaia. (n.d.). 20 different types of carbon capture. Gaia Company. Gaia. Department of Energy. (n.d.). Pre-combustion carbon capture research. Retrieved from Energy.gov

Global CCS Institute. (2012). CO₂ capture technologies: Pre-combustion capture. Retrieved from Global CCS Institute

Madejski, P., Chmiel, K., Subramanian, N., & Kuś, T. (2022). Methods and techniques for CO₂ capture: Review of potential solutions and applications in modern energy technologies. Energies, 15(3), 887. Retrieved from MDPI

Herzog, H., Meldon, J., & Hatton, A. (2009). Advanced post-combustion CO₂ capture. Massachusetts Institute of Technology. Retrieved from MIT.

John is a professional blogger and passionate advocate for environmental sustainability. With years of experience exploring eco-friendly practices and green innovations, he shares insightful articles on Planet Flagship to inspire a sustainable future. John’s expertise lies in making complex environmental topics accessible and actionable, empowering readers to make meaningful changes for the planet.